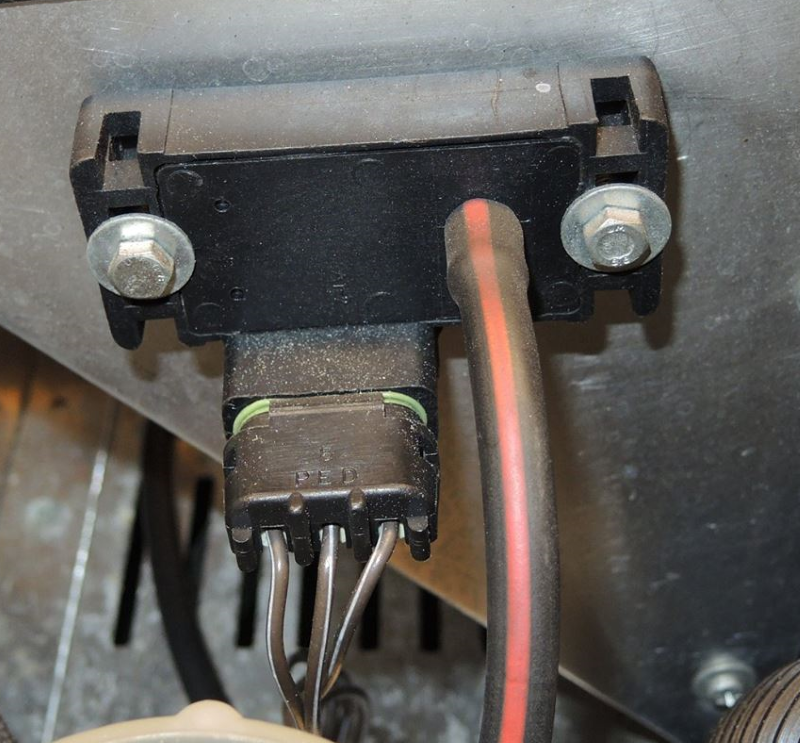

De eerste MAP-sensor (Manifolt Absolute Pressure). In het kort zet deze het vacuüm-signaal van het inlaatspruitstuk om in een electrisch signaal waar de computer iets mee kan doen. Deze zat op de kachelbak gemonteerd. Na verder onderzoek bleek deze verbonden te zijn met de connector voor het 'zilverkleurige kastje' en dus nutteloos te zijn. Deze MAP-sensor heb ik dan ook verwijderd.

Een kwoot van Internet over de werking van de MAP sensor:

MAP sensor function is to sense air pressure or vacuum in the intake manifold. The computer uses this input as an indication of engine load when adjusting air/fuel mixture and spark timing. Computerized engine control systems that do not use a MAP sensor rely on throttle position and air sensor input to determine engine load.

Under low-load, high-vacuum conditions, the computer leans the fuel mixture and advances spark timing for better fuel economy. Under high-load, low-vacuum conditions (turbo boost, for example), the computer enriches the fuel mixture and retards timing to prevent detonation.

The MAP sensor serves as the electronic equivalent of both a distributor vacuum advance diaphragm and a carburetor power valve.

The MAP sensor reads vacuum and pressure through a hose connected to the intake manifold. A pressure sensitive ceramic or silicon element and electronic circuit in the sensor generates a voltage signal that changes in direct proportion to pressure.

MAP sensors should not be confused with VAC (Vacuum) sensors, DPS (Differential Pressure sensors), or BARO or BP (Barometric Pressure) sensors. A vacuum sensor (same as a differential pressure sensor) reads the difference between manifold vacuum and atmospheric pressure (the difference in air pressure above and below the throttle plate). A VAC sensor is sometimes used instead of a MAP sensor to sense engine load.

A MAP sensor measures manifold air pressure against a precalibrated absolute (reference) pressure. What's the difference? A vacuum sensor only reads the difference in pressure, not absolute pressure, so it doesn't take into account changes in barometric (atmospheric) pressure.

A separate BARO sensor is usually needed with a vacuum sensor to compensate for changes in altitude and barometric pressure. Some early Ford EEC-III and EEC-IV systems have a combination barometric pressure/MAP sensor called a BMAP sensor, combining both functions.

Anything interfering with accurate sensor input can upset both fuel mixture and ignition timing. Problems with the MAP sensor itself, grounds or opens in the sensor wiring circuit, and/or vacuum leaks in the intake manifold.

Typical driveability symptoms include detonation due to too much spark advance and a lean fuel ratio, and loss of power and/or fuel economy due to retarded timing and an excessively rich fuel ratio.

A vacuum leak can cause a MAP sensor to indicate low manifold vacuum, causing the computer to think the engine is under more load than it really is. Consequently, timing is retarded and the fuel mixture is enriched.